Ibhanti yokuhambisa impahla yinxalenye ebaluleke kakhulu yenkqubo yokuhambisa impahla, esetyenziselwa ukuthwala izinto nokuzithutha ukuya kwiindawo ezikhethiweyo. Ububanzi nobude bayo buxhomekeke kuyilo lokuqala kunye noyilo lwendlelaibhendi yokuthutha.

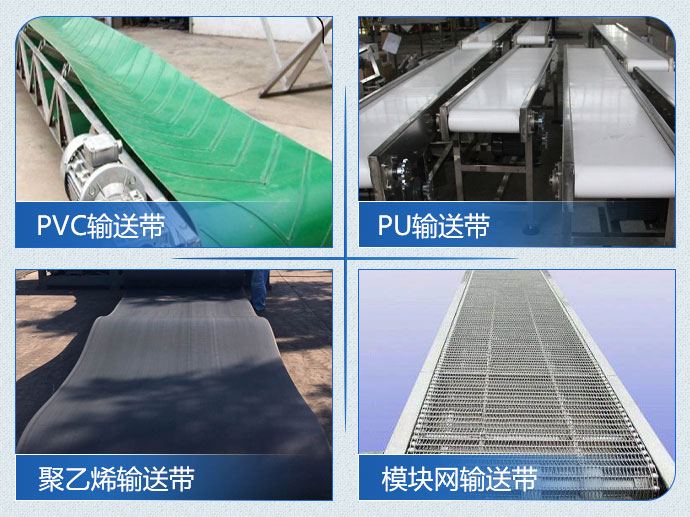

01. Uhlu lwebhanti yokuhambisa

Izixhobo zebhanti yokuhambisa eziqhelekileyo zingahlulwahlulwa zibe ziindidi ezimbini: enye yintsimbi yentsimbi engundoqo, enomthamo oqinileyo wokuthwala kunye neempawu ezilungileyo zomzimba nezoomatshini, ngoko ke inokuhlangabezana neemfuno zothutho olukhawulezayo phantsi kwesiseko somthamo omkhulu wothutho; Uhlobo lwesibini yinayiloni, umqhaphu, irabha kunye nezinye izinto, ezingaphantsi kancinci kunomthamo wothutho kunye nesantya sentsimbi engundoqo.

02. Ungayikhetha njani ibhanti yokuhambisa efanelekileyo?

Ukukhethwa kweibhanti lokubonisaUbungakanani bomthumeli webhanti busekelwe kwizinto ezifana nobude bomthumeli, umthamo wokuhambisa, uxinzelelo lwebhanti, iimpawu zezinto ezithuthwayo, iimeko zokwamkela izinto kunye nendawo yokusebenza.

Ukukhethwa kwebhanti yokuhambisa kuya kuhlangabezana neemfuno ezilandelayo:

Ibhanti yokuhambisa engundoqo yelaphu lepolyester kufuneka ikhethwe kwibhanti yokuhambisa emgama omfutshane. Kwibhanti yokuhambisa eneebhanti ezinomthamo omkhulu wokuhambisa, umgama omde, ukuphakama okukhulu kokuphakamisa kunye noxinzelelo olukhulu, kufuneka kukhethwe ibhanti yokuhambisa yentambo yentsimbi.

Izinto ezihanjiswayo ziqulathe izinto eziqinileyo ezinobukhulu obukhulu, kwaye xa ukuhla ngqo kwendawo yokwamkela kukhulu, kufuneka kukhethwe isixhobo sokuhambisa esimelana nokuchaphazeleka kunye nesimelana nokukrazuka.

Inani eliphezulu leeleya zebhanti yokuhambisa impahla engundoqo yelaphu elinomgangatho ophakathi akufuneki lidlule kwiileya ezi-6: xa izinto zokuhambisa impahla zineemfuno ezikhethekileyo kubukhulu bebhanti yokuhambisa impahla, zinokwandiswa ngokufanelekileyo.

Umthuthi webhanti ongaphantsi komhlaba kufuneka ube yinto ethintela ilangatye.

Isixhumi sebhanti yokuhambisa

Uhlobo oludibeneyo lwebhanti yokuhambisa kufuneka lukhethwe ngokwehlobo lwebhanti yokuhambisa kunye neempawu zebhanti yokuhambisa:

Ibhanti yokuhambisa intambo yentsimbi kufuneka isebenzise i-vulcanized joint;

Ijoyinti evulcanized kufuneka isetyenziswe kwibhanti yokuhambisa impahla engundoqo yelaphu elinamaleko amaninzi;

I-adhesive joint okanye i-mechanical joint kufuneka isetyenziswe kwibhanti yokuhambisa engundoqo yelaphu.

Uhlobo lwe-vulcanization joint yebhanti yokuhambisa: ibhanti yokuhambisa engundoqo yelaphu elineengqimba kufuneka isebenzise i-steped joint; Ibhanti yokuhambisa intambo yentsimbi inokusebenzisa i-vulcanized joint enye okanye ezininzi ngokwenqanaba lamandla okutyhafa.

Into yokhuseleko yebhanti yokuhambisa

Ukhuseleko lwebhanti yokuhambisa kufuneka lukhethwe ngokweemeko ezahlukeneyo: oko kukuthi, kwibhanti yokuhambisa ngokubanzi, ukhuseleko lwebhanti yokuhambisa intambo yocingo lunokuba ngama-7-9; Xa i-conveyor ithatha isiqalo esilawulekayo nesithambileyo, amanyathelo okuqhobosheka, afanelekileyo angama-5-7.

03. Ungayikhetha njani i-bandwidth kunye nesantya?

1. Ibhendiwidth

Ngokubanzi, ngesantya esithile sebhanti, amandla okuhambisa i-conveyor yebhanti ayanda ngokonyuka kobubanzi bebhanti. Ibhanti yokuhambisa kufuneka ibe banzi ngokwaneleyo ukuze iibhloko ezinkulu zebhloko ehanjiswayo kunye nomxube we-powder zingabekwa kufutshane nomphetho webhanti yokuhambisa, kwaye ubungakanani bangaphakathi be-chute yokutya kunye nomgama phakathi kwe-guide chute kufuneka zanele ukuvumela umxube wee-particles ezahlukeneyo ukuba udlule ngaphandle kokuvaleka.

2. Isantya sebhanti

Isantya esifanelekileyo sebhanti sixhomekeke kakhulu kuhlobo lwezinto eziza kuhanjiswa, amandla okuhambisa afunekayo kunye noxinzelelo lwebhanti olusetyenziswayo.

Ezi zinto zilandelayo ziya kuqwalaselwa xa kukhethwa isantya sebhanti:

I-bandwidth: okukhona ububanzi beteyiphu buncinci, kokukhona bungazinzi kangako xa busebenza ngesantya esiphezulu, kwaye bunokusasazeka kakhulu.

I-conveyor esisigxina: ngokubanzi, umgangatho wofakelo uphezulu, kwaye isantya sebhanti esiphezulu siyathandwa, ngelixa isantya se-conveyor esisisigxina nesihambayo siphantsi.

Xa kuthuthwa ngokuthe tye okanye phantse ngokuthe tye, isantya sinokuba phezulu. Okukhona ukuthambekela kukhulu, kokukhona kulula ukuqengqeleka okanye ukutyibilika kwezinto, kwaye isantya esisezantsi kufuneka samkelwe.

Ibhanti yokuhambisa enofakelo oluthambekeleyo: xa sithetha inyani, ibhanti yokuhambisa ezantsi kufuneka ibe nesantya esiphantsi, kuba izinto kulula ukuziqengqa nokuzityibiliza ebhantini ngexesha lokuthuthwa ezantsi.

Okukhona ixabiso leekhilomitha zetoni lomthamo wokuhambisa liphezulu, kokukhona kufuneka amandla ebhanti abe maninzi. Ukuze kuncitshiswe amandla ebhanti, isantya esiphezulu singasetyenziswa.

Ukugoba kwebhanti kwirola: impembelelo yokulayisha kunye nempembelelo yezinto ezisetyenzisiweyo zibangela ukuguguleka kwebhanti, ngoko ke kungcono ukunciphisa isantya sebhanti. Nangona kunjalo, ukuze kuncitshiswe uxinzelelo lwebhanti, iibhanti ezithwala umgama omde zihlala zisebenzisa ukusebenza ngesantya esiphezulu.

Umthuthi webhanti unokugqiba umthamo wokuhambisa ofunekayo kwinkqubo, omiselwa kakhulu bububanzi bebhanti kunye nesantya sebhanti. Isantya sebhanti sinempembelelo enkulu kububanzi bebhanti, ubunzima obungaphelelanga, iindleko kunye nomgangatho wokusebenza komthuthi webhanti. Phantsi komthamo ofanayo wokuhambisa, izikimu ezimbini zinokukhethwa: ububanzi bebhanti obukhulu kunye nesantya sebhanti esiphantsi, okanye ububanzi bebhanti obuncinci kunye nesantya sebhanti esiphezulu. Ezi zinto zilandelayo ziya kuqwalaselwa xa kukhethwa isantya sebhanti:

Iimpawu kunye neemfuno zenkqubo yezinto ezihanjiswayo

(1) Kwizinto ezinoburhabaxa obuncinci kunye namasuntswana amancinci, afana namalahle, iinkozo, isanti, njl.njl., kufuneka kusetyenziswe isantya esiphezulu (ngokubanzi i-2 ~ 4m/s).

(2) Kwizinto ezirhabaxa kakhulu, iibhloko ezinkulu kunye noloyiko lokutyumza, ezifana namalahle amakhulu, i-ore enkulu, i-coke, njl.njl., isantya esiphantsi (ngaphakathi kwe-1.25 ~ 2m/s) siyacetyiswa.

(3) Kwizinto ezinjengomgubo okanye izinto ezinothuli oluninzi olulula ukuluphakamisa, kufuneka kusetyenziswe isantya esiphantsi (≤ 1.0m/s) ukuze kuthintelwe ukubhabha kothuli.

(4) Kwiimpahla, izinto eziqengqelekayo okanye kwiindawo ezineemfuno eziphezulu kwiimeko zempilo yokusingqongileyo, isantya esiphantsi (≤1.25m/s) sifanelekile.

Indlela yokubeka kunye nokukhupha i-conveyor yebhanti

(1) Iibhanti ezithwala iibhanti ezikude nezithe tye zinokukhetha isantya esiphezulu sebhanti.

(2) Kwizithuthi zebhanti ezinomgama omde okanye omfutshane wokuhambisa, isantya sebhanti masincitshiswe ngokufanelekileyo.

(3) Xa itroli yokukhulula impahla isetyenziselwa ukukhulula impahla, isantya sebhanti akufuneki sibe phezulu kakhulu, ngokubanzi singabi ngaphezu kwe-3.15m/s, kuba indlela ethambekele ngayo ibhanti yokuthutha impahla kwitroli yokukhulula impahla inkulu.

(4) Xa isixhobo sokukhupha inkunkuma sisetyenziselwa ukukhupha inkunkuma, isantya sebhanti akufuneki sidlule kwi-2.8m/s ngenxa yokumelana nokongezelelekileyo kunye nokuguguleka.

(5) Isantya sebhanti somthuthi webhanti ehlayo onethambekele elikhulu akufuneki sidlule kwi-3.15m/s.

Ibhanti yokuhambisa yeyona nto iphambili kwi-conveyor, eyinxalenye yebheri kunye nenxalenye yokutsala. Ixabiso lebhanti yokuhambisa kwi-conveyor libalelwa kwi-30% - 50% yexabiso lilonke lezixhobo. Ke ngoko, kwi-conveyor belt, kufuneka kuqwalaselwe ukukhethwa kwezinto, isantya sebhanti kunye nobubanzi bebhanti ukuqinisekisa ukusebenza okusebenzayo nokuzinzileyo kwe-conveyor.

Iwebhu:https://www.sinocoalition.com/

Email: sale@sinocoalition.com

Ifowuni: +86 15640380985

Ixesha lokuthumela: Jan-11-2023